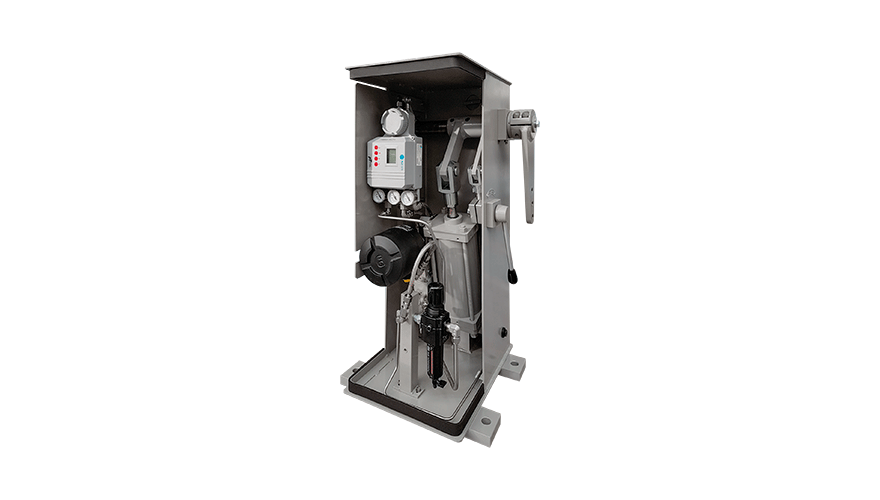

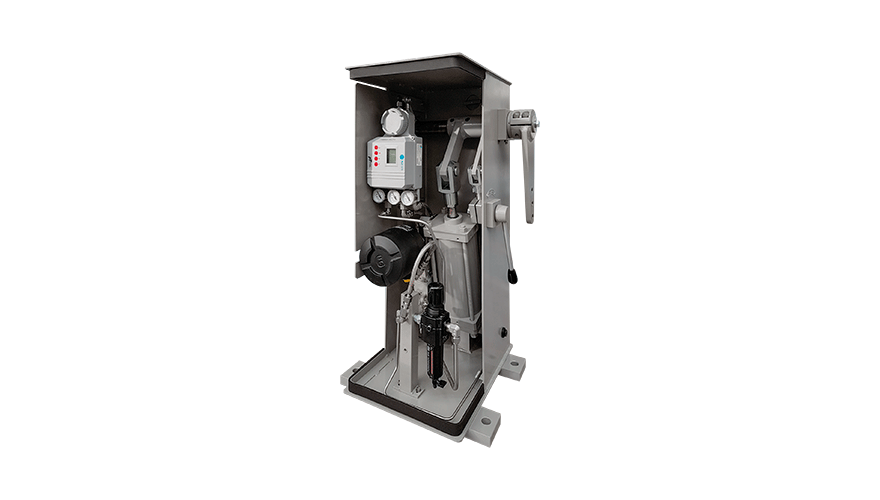

CML pneumatic actuator system consists of an actuator and a manual override integrated into a steel housing which is also a portable structure. This rugged construction guarantees continuous operation in harsh environments, for example in power stations, steel industries, petrochemical plants, desert areas.

This actuator is able to control final elements like dampers, butterfly valves, speed variators, radial vanes, providing torque up to 100 daNm. Manual operation is by a clutchable lever, equipped with a mechanical system. This system allows the movement of the actuator through an external lever and locks it in the required position.

|

Operating pressure Pneumatic version up to 10 barg (special version available on request) |

Standard operating temperature -20°C to 70°C (lower or higher temperature on request) |

|

Sizes for CML-1 63/125 100/100 |

Sizes for CML-2 100/200 125/200 |

|

Working lever operating angle 63/125 and 100/100 = 90° 100/200 and 125/200 = 70° |

Housing Carbon steel

|

|

Certifications/approvals PED 2014/68/EU ATEX 2014/34/EU IP66 according to IEC/EN 60529 (further certifications are available, please contact us for updated list) |

|